Shellfish after treatment for 2 min @ 6000 bar. Fresh, juicy and tasty!

The available litterature in English (including blogs) on popular food science focuses mainly on Western cooking, although the academic litterature on Asian foods is catching up quickly. Although widespread and apparently “well known”, Asian cooking is still largely being referred to in broad categories such as Chinese, Indian etc. Having spent 10 years of my childhood in Asia I’ve always had the feeling that this wasn’t quite right, and I do indeed look forward to learn more about the science aspects of Asian food in the years and decades to come. In one of the breakout sessions (more about those in a separate post) Alok Nandi made a point that Indian cuisine is as diverse as the European cuisine. With this background it is interesting to note that two of the chefs presenting at The Flemish Primitives 2010 had taken their inspiration from Asia.

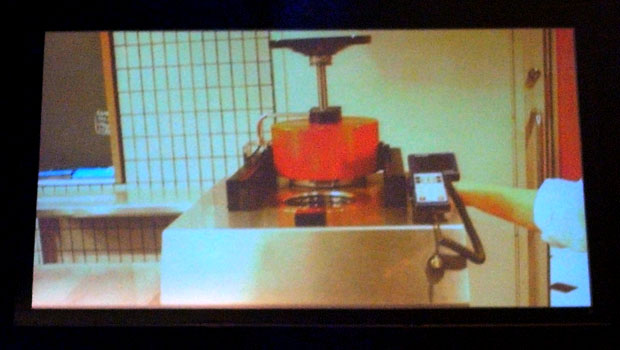

Japanese pressure treatment vessel (picture from Peter Goossens powerpoint presentation)

On a study trip to Japan, Peter Goossens (chef at Hof Van Cleve) and 15 other chefs were apparently the first Europeans admitted to the Hattori chef’s school (Wikipedia entry – I’m not 100% sure if this is the right “Hattori”) for a 3 day intensive course. One thing they were served were sardines treated at a pressure of 1000 bars. They were surprised by the texture and flavor, and when talking to Bernard Lahousse about it he put them in contact with Stefan Töpfl at the German Institute of Food Technologies. Töpfl’s group works with food processing, and one topic of interest is high pressure processing: it turns out that treating food for 2 min @ 6000 bar is an efficient way of pasteurizing (see for example an article from the institute on poultry pasteurization).

Stefan Töpfl being interviewed by Bernard Lahousse. Peter Goossens in white jacket relaxing at the bar. Photo by Piet De Kersgieter

But there is more to high pressure processing than pasteurization. Oysters, clams and shellfish in general for instance are vacuum packed and the pouches are water cooled throughout the process. This allows for “cold pasteurization”. Apart from the fact that no heating is involved (and hence the flavor remains unaltered) there are several other benefits of the heating process: oysters nearly double in size and “fill the shells”, shellfish are generally easier to open, crustaceans are easily descaled, taste is enhanced and there is less need for salt. The technique can also be applied to other foods such as fruit which turns sweeter after the high pressure treatment. The explanation for the enhanced taste and sweetness is that the water binding capacity of the foods increases, and hence there is more free water to dissolve and carry tastes. Other applications include treatment of guacamole for retention of the green color and flavor impregnation (i.e. oysters impregnated with champagne!).

Every single attendant to TFP2010 was served a plastic tray with four different high pressure processed clams/shellfish/oysters (I admit that I’m confused by the nomenclature here – seems there are differences between languages as well as to how generic the terms are used)

Quite surprisingly shellfish samples were handed out as you can see from the pictures. In my opinion they were very juicy, not stringly, a little salty and had a fresh taste. But I have to admit that I eat shellfish so seldomly that it’s hard for me to really compare the high pressure treated ones to more conventional shellfish. As Bernard Lahousse was called up on the stage he also presented a flavor pairing tip for oysters based on methyl hexanoate, which they interestingly share with kiwis (and passion fruit!). Many more flavor pairing tips can of course be found on the the foodpairing website. And the foodpairing blog published the recipe for Kiwí®tre in 2007, a dish invented by Sang Hoon Degeimbre (chef of L’air du temps) which combines oysters and kiwi.

Bernard Lahousse explaning how kiwis and oysters have methyl hexanoate in common.

Further reading: A quick google search yields numerous hits on high pressure processing of food, including the companies High Pressure Dynamics and Avure which manufacture the processing equipment. There are many scientific publications on the topic (including one on high pressure induced gel of sardine – perhaps this is this what Peter Goossens and his colleagues were served when visiting Japan?), and wikipedia also has a nice introduction to high pressure food preservation. Youtube has several videos demonstrating HPP.

Next up from TFP2010: more Asian inspiration with Sang Hoon Degeimbre and kimchi!

–

I also visited The Flemish Primitives in 2009. You can read more about that in my four posts from last year: The Flemish Primitives: A travel report (part 1), Chocolate surprise (part 2), Heston Blumenthal (part 3) and Glowing lollipops (part 4). Final note to readers: This year my travel expenses were covered by TFP and the tourism bureau of Brugge.

I believe a New Zealand company uses this technique for long storage mussels, a friend uses them at his Cafe.

Amazing, I’d have thought high pressure treatment would totally flatten a product. A friend who fishes in Alaska for salmon, was telling me yesterday how often fish get thrown into a boat and the ones at the bottom are “pressure treated”, or smashed to a squishy consistency, when too many are piled on top. I know the purposeful technique you’re discussing is something completely different, but difficult to imagine all the same. Just my ignorance.

Very interesting as for the last several years, much discussion has been made around sous-vide and other applications where pressure is removed. I’m very surprised there’s not more cellular damage to the clam at 6K bar (I am reading this correctly as 6K times sea level?).

[…] que se produjo en BCN Vanguardia. Os recomiendo que visitéis el blog de Khymos, la entrada de TFP 2010: Inspiration from Asia (part 2), donde habla de la experiencia de la aplicación de las Altas Presiones Hidrostáticas de Stefan […]